Tumbling / Dusting

Prior to scouring, the wool as it comes from the sorter is in the majority of cases passed through a machine known as a duster. The object of dusting grease wools is, as far as possible, to remove before the scouring impurities such as lumps of dirt, dust etc. The reason for this is that, as all such impurities are damaging to the finished goods and to the mills equipment. It is best to remove them at as early a period as possible. It is particularly important to have the wool as free from foreign matter as possible before it is scoured, as the saving in soap and scouring liquor when the wool is dusted and freed from sand, chaff, etc. is very apparent.

Another object, although a subsidiary one, is to deliver the wool to the scouring machine in a more open and lofty condition, as we have found that scoured wool which has previously been passed through a duster leaves the washing machine more thoroughly and evenly scoured and brighter looking. The reason for this is that the stock is not only partly cleaned by the dusting, but is also opened up so that the scouring liquor will penetrate every portion of it and thus render the scouring more even and more thorough.

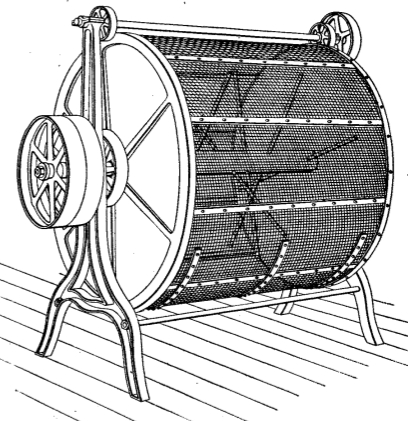

A duster commonly used in smaller mills is shown at right. The machine consists of a large rotating horizontal cylinder covered with heavy wire screening. Inside the cylinder is a central shaf t on which are fixed eight iron cross bars about 5 feet long. The cylinder has a door through which the stock may be entered and removed.

t on which are fixed eight iron cross bars about 5 feet long. The cylinder has a door through which the stock may be entered and removed.

In operation, the wool is placed in the duster and the iron cross-bars, which rotate, beat out all the dust and dirt from the wool and force it through the screen-covered cylinder.

We use a more modern adaptation of this kind of duster. The cage is hexagonal in construction with each side capable of being removed to add or remove wool. Sets of fingers have been attached to the sides of the hexagon sticking in at various angles to beat the dust and dirt out of the wool as the cylinder rotates.

Here are some pictures of our duster under construction

and below is the finished duster in operation.

- Columbia Custom Carding LLC

- 31525 Canaan Rd

- Deer Island, Oregon 97054

- 503-410-3152 (Mill)

- mich@cccarding.com

- Hours M-T 10-5:00 (mill by appointment only)